The dynamic centrifugal separation ensures barrier-free separation of grinding media from materials with smooth discharge and the minimum size of grinding beads being 0.03mm to which makes grinding of materials below 100nm possible.

Advantages

- No separation screen needed, smooth discharge

- Narrow and even particle distribution

- The minimum size of grinding beads can be 0.03mm

- Ultra-fine nano grinding below 100nm

Permanent Magnet Driven Sand Mill

This equipment is a new generation of high efficiency nano wet grinding equipment specially developed for mass production of LFP. Its output, internal structure, manufacturing process, material and other aspects have been optimized and upgraded, its grinding efficiency and energy consumption indicator better than the industry average.

Applications

Digital inkjet, printing ink, lithium battery materials, ceramic materials, conductive materials, etc.

Advantages

- Special rotor design can increase the activity of grinding beads and the grinding efficiency is 1.3-1.5 times that of conventional bead mills

- High constant torque start, direct connection installation, no need for drive belt

- Unique cooling system ensures grinding temperature easily controlled so that no heat exchanger is required

- Unique dynamic separation structure enables efficient separation of materials and grinding beads with smooth discharge

- Large batch size for a single machine, so the cost is reduced in terms of input costs, consumables, maintenance, labor, etc

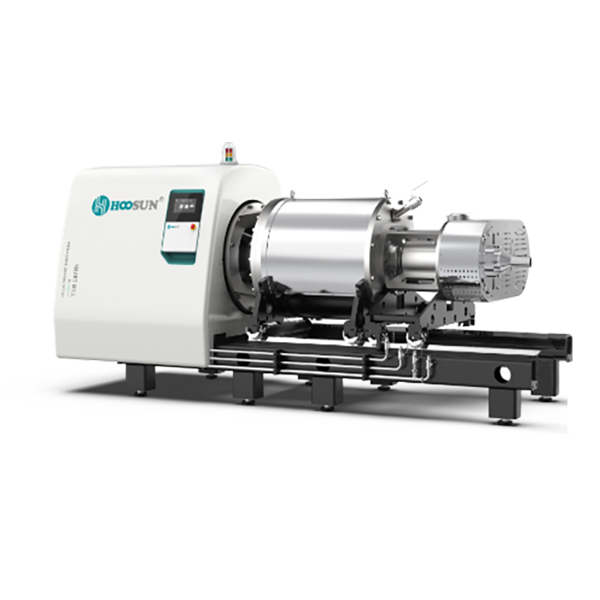

Dual Power Permanent Magnet Driven Sand Mill

The new large capacity nano mill developed by HOOSUN is the core equipment of silicon carbon anode materials, applicable to various materials with high fineness and large output requiremens

Applications

Si-C Anode Materials, Nano-TiO2, MLCC, Ink Jet, Buffing and Polishing Materials, LCD, other nano materials etc.

Advantages

- Innovative structural design, with independent intellectual property rights

- Narrow particle distribution, high batch stability

- Production efficiency is twice that of imported equipment, achieving import substitution

- Large output can reduce production costs and achieve the industrialization of material preparation

- 0.03mm grinding bead size can be used, and minimal achievable particle size below 30nm

HOOSUN basket mill has a unique dispersing and grinding system, and the dispersing shaft drive in the grinding chamber is independent. Its production operation is very flexible, and the energy input in the grinding area is different from that in the input basket, which has a great advantage over other single-shaft basket mill structures on the market.

Application

Printing ink, coating and other fine chemical industry

Advantages

- Unique dispersing and grinding system can improve material grinding efficiency

- Intelligent hydraulic lifting system, easy to achieve production automation and intelligence

- Applicable to wide range of product viscosity

- No pumps and pipes, no mechanical seal

- High flexibility of batch sizes with various tank sized